Become confident decision makers.

Use NLign Analytics to advance aircraft safety and efficiency in your organization.

Manual data-keeping is incomplete and error prone, which is aggravating.

Because of this, engineers and managers (through no fault of their own):

-

Waste time performing redundant analysis

-

Have an incomplete picture of the state of each aircraft

-

Risk losing aircraft information if staff leave, because it’s stored in their heads

-

Miss fleet-wide structural integrity trends

-

Unable to improve processes and cost schedules

Credit: National Museum of the U.S. Air Force.

Whether your challenge is sustainment or manufacturing, NLign has the solution.

NLign’s sophisticated aircraft modeling software delivers instant access to fleet-wide data.

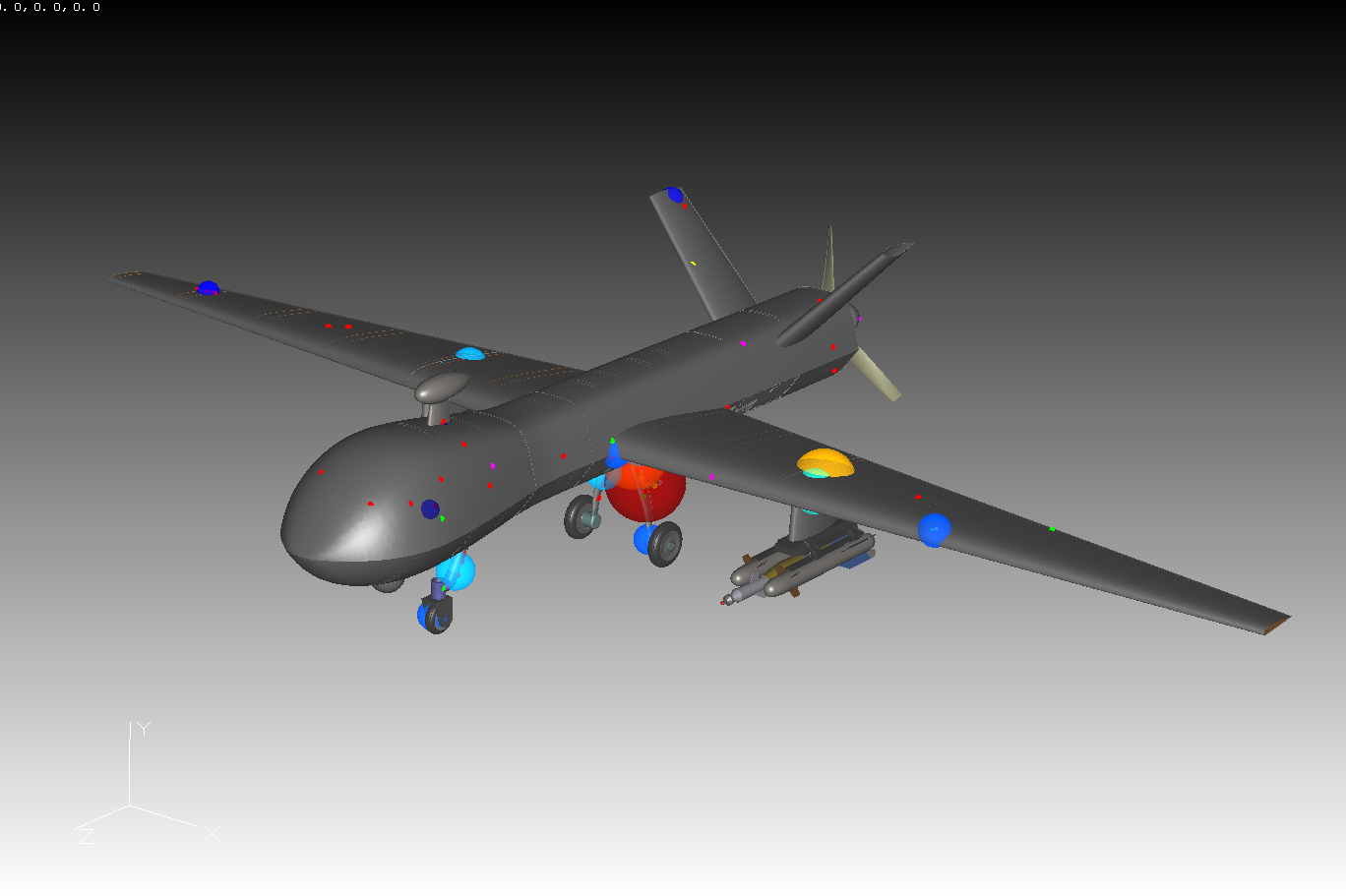

Visualize accurate and complete 3D models of your as-maintained aircraft. Every data point engineering and operations need to make confident decisions is in front of you. Instead of flying blind, the team is empowered to solve problems quickly.

- Instantly identify relevant historical analysis on 3D models

- Gauge risk

- Improve aircraft availability

- Reduce maintenance costs

- Identify defect trends

- Avoid frustrating rework

- Gain understanding of aging aircraft maintenance cycles

Northrop Grumman estimates NLign saves 33% of manufacturing material review board (MRB) labor hours on F-35.

The USAF A10 Program has seen improvements from 15% usable data without assumptions before NLign to 95% usable data with NLign deployed.

Comprehensive aircraft data is now at your fingertips.

NLign system transforms the entire, tedious search process into a click. And it takes weeks (not years) to implement, with little learning curve.

Developed together with engineers, NLign Analytics is a recognized name in the DOD.

We’ve earned our stripes in the DOD because for over 15 years, we’ve worked side-by-side to deliver critical data and empower them to operate their systems without needing consultants. NLign focuses on issues pertinent to structural integrity within manufacturing, sustainment, and MRO.

- US Navy F-18 Chief Structural Engineer

— Naval Air Systems Command

Science & Engineering Vector: Volume 2 / Issue 1

In this Issue:

- Senior Leadership Viewpoint

- Digital Engineering at Your Service

- Protected Tactical Enterprise Service (PTES)

- Integrating Systems Security Engineering into Systems Engineering

- Engineering Leadership Moves

- AFRL Puts New Technologies into Space

- LCID Industry Engagement on a Growth Curve

- Digital Engineering Training at AFNWC Defining and Developing the Digital Groundwork to Realize Tangible Tactical Advantages

NLign Analytics Enables Model-Driven Product Quality

NLign Analytics creates a robust 3D “Structural Lifecycle Digital Environment” for each weapon system, tracing structural integrity data from manufacturing through quality inspection and sustainment…

- Don Tolle

Practice Director, Simulation-Driven Systems Development, CIMData

See how NLign helped double the service life of the A-10.

[The A-10 program] adopted a new technology, NLign, to map repairs onto the 3-D model. [This] allowed A-10 to construct the digital thread for the sustainment phase of the lifecycle…”

- Michael D. Griffin

Under Secretary of Defense for Research and Engineering, U.S. Department of Defense

A transparent process for implementation.

Like you, we care about making fully informed decisions. That’s why our experts carefully plan and prove out your solution.

Discovery

Set-Up and

Historical Data Loading

Integration

Training

A transparent process for implementation.

Like you, we care about making fully informed decisions. That’s why our experts carefully plan and prove out your solution.

Discovery

Set-Up and

Historical Data Loading

Integration

Training

A transparent process for implementation.

Like you, we care about making fully informed decisions. That’s why our experts carefully plan and prove out your solution.